Ensuring Quality in Wire Harness Manufacturing: A Comprehensive Guide to Testing Procedures

Wire harnesses are a vital component in various industries, connecting and transmitting power, signals, and data in a wide range of applications. Ensuring the reliability and safety of wire harnesses is crucial, and this is achieved through rigorous testing procedures. In this blog post, we will delve into some of the key testing procedures used in wire harness manufacturing, including crimp cross-section analysis, pin-to-pin testing, hipot testing and pull force testing that guarantee the quality and performance of wire harnesses.

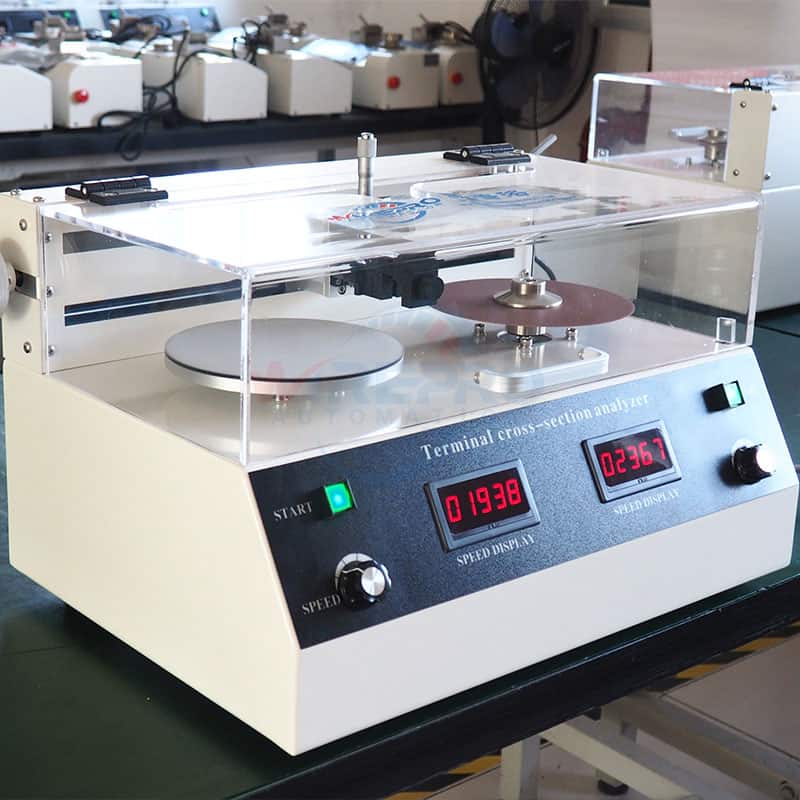

Crimp Cross-Section Analysis

One of the critical aspects of wire harness manufacturing is the quality of crimps, which are used to secure wires to connector pins. Crimp cross-section analysis is a thorough examination of the crimped area to ensure it meets specifications..

This procedure involves cutting a crimped terminal perpendicular to the wire's axis and carefully examining the resulting cross-section. Visual and microscopic inspections are performed to assess the crimp's form, wire placement, compression uniformity, and strain relief. Critical dimensions like crimp height, conductor encapsulation, and wire diameter are measured. This meticulous inspection ensures that the crimped connections meet quality and reliability standards.

Pin-to-Pin Testing

Pin-to-pin testing, also known as continuity testing, verifies that each wire in a harness is correctly connected. This test uses automated testers or multimeters to confirm electrical continuity between corresponding pins at each end of the harness, detecting short circuits and ensuring proper resistance levels. This procedure is essential for ensuring the functionality and reliability of the wire harness.

Hipot Testing (High-Potential Testing)

Hipot testing, short for high-potential testing, evaluates the electrical insulation of wire harnesses. It involves applying a high voltage between conductive and non-conductive parts of the harness to simulate extreme conditions. During the test, insulation resistance is monitored to detect leakage or faults. The harness must withstand the specified voltage without exceeding allowed leakage current to pass this crucial test, ensuring its reliability and safety.

Pull Force Testing

Pull force testing evaluates the mechanical integrity of wire connections within a harness. A controlled force is applied to wires or connectors using specialized equipment, simulating real-world stress conditions. Consequently, the wire is consciously disconnected with the terminal to measure the force to be applied for the disconnection.

The test detects issues like loose wires or insufficient crimping. To pass, the harness must withstand the specified pull force without damage or disconnection, ensuring its mechanical reliability.